Building Trust Through Plan-Do-Check-Act Cycles

The Foundation of Trust

Think about why we trust our government institutions—not because they're perfect, but because they operate on structured systems designed (in the best of times) for accountability, transparency, and continual improvement. This same principle applies to any organization, whether you're running a non-profit, a small business, or a grassroots community initiative.

A management system isn't bureaucracy for its own sake. It's the foundation that builds trust—with your team, your stakeholders, your community, and yourself. It's the structure that ensures you're not just reacting to problems, but continuously improving how you operate.

The key? Keep it clear. Only implement the essential processes your organization actually needs.

What is PDCA?

PDCA stands for Plan-Do-Check-Act—a continuous cycle of improvement that forms the backbone of effective management systems worldwide. It's recognized in ISO 9001, required in regulated industries, and proven across organizations of every size.

The beauty of PDCA is its simplicity: you plan what you'll do, you do it, you check if it worked, and you act on what you learned. Then you start the cycle again, always improving.

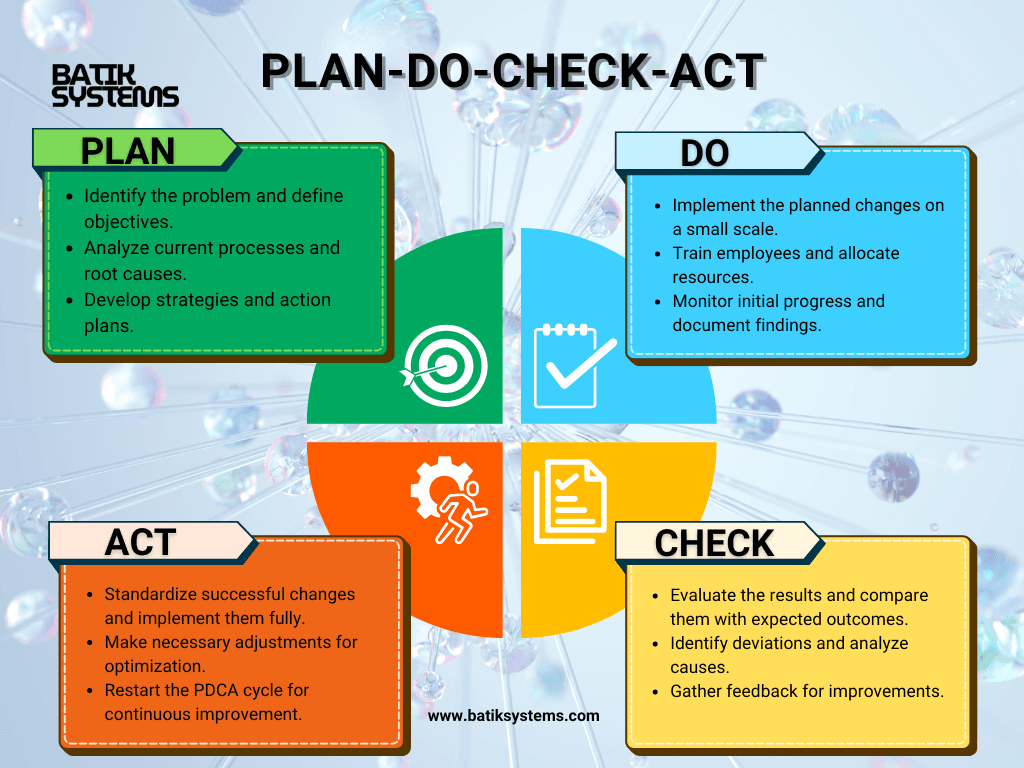

The PDCA cycle: A continuous loop of improvement

Understanding the PDCA Cycle

Let's break down each phase of the cycle and understand what it really means in practice:

PLAN - Setting Your Foundation

This is where you establish your direction. You're not just setting goals—you're identifying problems, analyzing their root causes, and developing thoughtful strategies to address them.

Key activities:

Identify problems and define clear objectives

Analyze current processes and understand root causes

Develop strategies and action plans

Set up the framework for success

Think of planning as building your roadmap. You wouldn't start a road trip without knowing your destination and route—the same applies here.

DO - Executing Your Plans

Implementation phase. This is where you put your plans into action, but you start small and deliberate. You're not rolling out everything at once—you're testing on a small scale, training your team, allocating resources, and carefully documenting what happens.

Key activities:

Implement planned changes on a small scale first

Train employees and allocate necessary resources

Monitor initial progress and document findings

Execute with intention and awareness

The "Do" phase is about controlled execution. You're learning as you go.

CHECK - Evaluating Your Results

Now you measure and evaluate. Did your plan work? Are the results what you expected? This phase is about honest assessment—comparing your actual outcomes against your targets, identifying gaps, and gathering feedback.

Key activities:

Evaluate results and compare them with expected outcomes

Identify deviations and analyze their causes

Gather feedback for improvements

Measure what matters

Checking isn't about judgment—it's about learning. What worked? What didn't? Why?

ACT - Making It Stick

The final phase is where improvement becomes permanent. If something worked, you standardize it across the organization. If something didn't work, you make adjustments. Then you restart the PDCA cycle, because improvement never stops.

Key activities:

Standardize successful changes and implement them fully

Make necessary adjustments for optimization

Document lessons learned

Restart the PDCA cycle for continuous improvement

This is where good ideas become organizational habits.

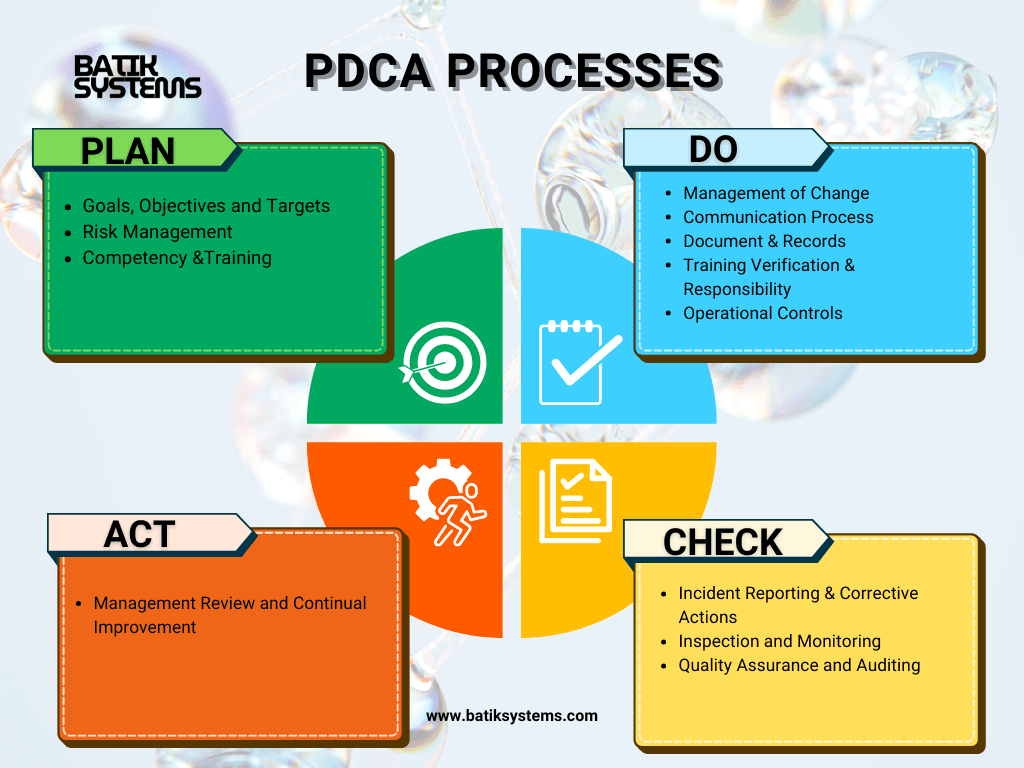

How PDCA translates to practical management activities

PDCA in Your Management System: The Essential Processes

Now let's get practical. Here's how PDCA translates into the actual management system processes your organization needs—simplified for grassroots and small organizations. Note that the processes can be shifted around under the PDCA if your organization already does things a little differently.

🟢 PLAN - Three Core Planning Processes

1. Goals and Performance Process Set clear objectives and targets that support your organization's mission. Define how you'll measure success. Review annually to stay aligned.

Why it matters: Without clear goals, you're just busy—not effective.

2. Hazard and Risk Management Process Identify what could go wrong (hazards), assess the risks, and develop controls to prevent or mitigate them. Ensure you're compliant with legal requirements and have contingency plans for abnormal events.

Why it matters: Prevention is always cheaper than crisis management.

3. Competency and Training Program Process Define what skills your team needs and create training programs to develop those competencies. Ensure everyone can perform their duties safely and effectively.

Why it matters: Your people are your most valuable asset—invest in them.

🔵 DO - Five Implementation Processes

1. Document and Records Management Process Create, control, and maintain the documents and records you need. Keep them organized, accessible, and up-to-date.

Why it matters: If it's not documented, it didn't happen. Good records protect you and prove your performance.

2. Management of Change Process Before making changes that could affect safety, security, or the environment, assess them systematically. Manage new risks that come with change.

Why it matters: Change is inevitable, but it shouldn't be chaotic.

3. Training Verification and Responsibility Awareness Process Verify that people are actually trained and competent. Make sure everyone understands their responsibilities. Provide supervision and support.

Why it matters: Training only works if people actually learn and apply it.

4. Communication Process Establish clear channels for internal and external communication about safety, security, and environmental matters.

Why it matters: Information only helps if it reaches the right people at the right time.

5. Operational Coordination and Control Process Coordinate activities so everyone knows what others are doing and has the information they need to work safely and effectively.

Why it matters: Silos create gaps. Coordination creates safety.

🟡 CHECK - Three Monitoring Processes

1. Incident Reporting and Corrective Action Process Create a system for reporting hazards, near-misses, and incidents. Take corrective and preventive actions promptly, especially for imminent hazards.

Why it matters: Near-misses are warnings. Listen to them before they become incidents.

2. Data Analysis and Inspection Process Track trends in hazards, incidents, and near-misses. Inspect and monitor your activities and facilities. Identify patterns before they become problems.

Why it matters: Data tells stories. Learn to read them.

3. Management System Evaluation and Audit Process Regularly evaluate whether your management system is actually working. Conduct audits. Measure performance. Be honest about gaps.

Why it matters: What gets measured gets managed. What gets audited gets taken seriously.

🟠 ACT - One Critical Improvement Process

1. Management Review and Continual Improvement Process Conduct annual management reviews of your entire system. Identify opportunities for improvement. Make decisions. Follow through. Never stop improving.

Why it matters: This is where the cycle completes and restarts. This is where organizations become excellent.

Making It Work for Your Organization

The PDCA framework isn't one-size-fits-all. A grassroots volunteer organization will implement these processes very differently than a 50-person manufacturing company. That's okay.

The principles remain the same:

Plan thoughtfully before you act

Execute deliberately with training and coordination

Monitor honestly what's actually happening

Improve continuously based on what you learn

Start with the processes you need most. Maybe that's just setting clear goals and tracking incidents. Build from there. The framework can grow with you.

The Return on Investment

Implementing a management system requires effort. It requires discipline. But here's what you get in return:

Trust - From your team, stakeholders, and community

Clarity - Everyone knows what's expected and how to succeed

Resilience - Problems get caught early and fixed systematically

Improvement - You get better every year, not just busier

Compliance - You meet legal requirements and can prove it

Peace of mind - You're building something sustainable

Your Next Steps

Assess where you are today - What processes do you already have, even informally?

Identify your biggest gap - Where do problems keep happening?

Start with one process - Don't try to implement everything at once

Document what works - Keep it simple, keep it accessible

Review and improve - Set a date to check how it's going

Remember: Lean doesn't mean weak. It means focused on what matters.

Your organization deserves a foundation it can build on. PDCA gives you that foundation.

Conclusion

Management systems aren't just for big corporations or heavily regulated industries. They're for anyone who wants to build something that lasts, something that improves, something that people can trust.

Whether you're running a community garden, a small business, a non-profit advocacy group, or a local service organization, these principles apply. Plan thoughtfully. Execute deliberately. Monitor honestly. Improve continuously.

That's PDCA. That's how organizations build trust through structure.

Ready to implement PDCA in your organization? Start with one process this quarter. Document it. Test it. Improve it. Then move to the next one. Progress over perfection.